Simulating Performance of Extended-Reach SAGD wells – part 2

Welcome back to Madala’s Wellbore Wednesdays. Last week we started a series about simulating the performance of extended-reach SAGD wells. We took a generic ESP producer with a tailpipe and a 1000 m liner, and extended it to a 1800 m liner to see what rates might be achievable. The goal was to see if an an 80 % longer liner could deliver 80 % more flow, however the best we could reach was 40 % more flow. If you missed the article, you can get caught up here:

Simulating Performance of Extended-Reach SAGD wells – part 1

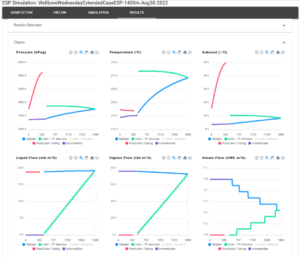

Given that we could only reach a 40 % flow increase because of hydraulic limitations, we decided to examine the performance with an evenly-distributed 40 % flow increase through a 40 % longer liner of 1400 m. The simulation results are below.

With the shorter liner, the hydraulics still look restrictive. The liner annulus from the heel to the toe is losing about 200 kPa. Assuming a constant pressure of 3400 kPag along the outside of the liner, the heel will draw less emulsion than the toe because of the higher liner pressure. This isn’t good for conformance. The tailpipe loses another 675 kPa which produces a lot of gas for the separator.

After last week’s article, we had some discussions internally and with various people. The challenge with an extended-reach well like this is that with a 7 inch liner and 4.5 inch tailpipe, there’s a limit to how much fluid you can pull through at low subcool. Larger-diameter liners and tailpipes might be feasible but they’re harder to land and more expensive. Looking at the results, the tailpipe is constraining rates through pressure loss. We decided to look at a completion with a liner and no tailpipe, 1800 m long and with the full 80% increase in rates. Credit is also due to Tom Rawson from MEG Energy who had the same idea. The results are below:

With no tailpipe restricting flow in both directions, the liner is only losing 30 kPa from the toe to the heel. The overall gas flow is higher than the 1400 m case, but the liquid rate is 30% higher so the gas fraction reaching the ESP separator is lower. This completion has a lot more potential for higher rates with more drawdown. There’s also the capital, ESG and time savings associated with not procuring, shipping, assembling and landing a tailpipe.

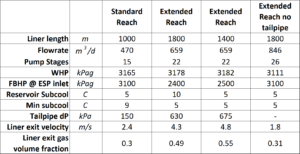

So far we’ve done four simulation analyses, summarised in the table below:

For extended-reach wells, minimizing pressure loss is important, because once multiphase flow begins, frictional losses drive themselves as gas evolves out of the emulsion.

Next week we’ll look at developing an inflow model for the extended-reach, no-tail completion and see what further flow increases might be achievable. In the meantime, please reach out to Raj Bal, Stan Cena or Damien Hocking if you’d like to learn more, and follow us to keep up on the Wellbore Wednesday series.